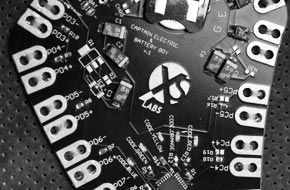

CEBB – PCB

The Captain Electric circuit board is designed by Vincent Leclerc at ESKI studios in partnership with XS Labs. The PCB functions to convert AC electricity from various dynamo sources to DC and to store that energy in a detachable 3.6 Volt ion-lithium battery, providing power for the Atmel micro-controller, which can power and control various input sensors and outputs. There is also an integrated connection for a power accumulator which can increase the power gathering and storing abilities of the circuit.The PCB itself also includes connections to integrate charge controllers, but they were, after additional testing, found to consume too much of the generated power, and so the benefits of this addition were lost. The PCB is designed with conductive sewing pads to allow for the connection of inputs and outputs via conductive threads, and a rainbow of 5 LEDs are integrated for various debugging purposes.

STICKY – Power Dynamos

Three geared-up pulley-dynamos power Sticky. The dynamos are held in place on the inside of shaped plastic Sintra shells with metal bracing, screwed and bolted in place, while the handles of the pulleys stick through slit-openings. The hard shells, which are upholstered with embroidered leather, are strapped to the body using polyester straps and plastic fasteners in order to keep them firmly in place on the body.The cylindrical dynamos are positioned and angled within the shells to follow the range of motion that the arms will make. As the motion generated by this design is outward from the body, little stress is put on the pulleys themselves, but rather it is largely focused on the straps, which can easily take the abuse. The black plastic pulley handles are connected to the sleeves of the dress (around the wrist area) via metal hooks sewn into recessed openings in the sleeves of the dress.

STIFF – MP3 Controller

Stiff's requirements obliged programming that would provide adequate control of an mp3 player. Due to the interface of the mp3 player, the most prevalent issue in programming was finding the optimal delay times between switch actuating in order to start, play and maximize the volume of the mp3 player. To safely and reliably interface with the mp3 player an additional circuit board incorporating digital switches was integrated directly into the mp3 player with mosfets added to the cebb board to deliver sufficient power to the player.The small PCB essentially houses 2 digital switches; 1 to control the 'on/off/play/pause' switch, and 1 to control the 'volume up' switch. Integrating these surface mount components onto a small PCB, allow for minimal wire connections, while maintaining a low profile to be able to fit the components safely into the mp3 player housing.

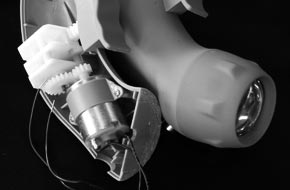

STIFF – Power Dynamo

The generator used for this dress comes from a push-motion dynamo flashlight. Due to the unusual ergonomic shape of the flashlights attempts were made to remove the dynamo mechanism from the body of the flashlight, but these attempts all yielded a substantial decrease in power-generating efficiency. Therefore the entire flashlight casing is integrated into the garment.We formed a Sintra back-piece that followed the contours of the back that could be strapped on like a backpack. Because of the relatively high force of impact required to generate power, and the unusual shape of the flashlights, we used Dragon Skin Silicone as a buffer between the dynamos and the back-piece. These silicone-molded support bases minimize the possibility of damage to the dynamos, while not noticeably adversely affecting power generation.

Each dynamo’s push button has a 5” diameter Sintra disc attached via a plywood adaptor, giving a large surface to push on to generate power. In order to fill out the shape of the back, foam padding was placed between the dynamos, and a neoprene cover was made for the entire back-piece, in order to keep the parts safe, and aesthetically ‘smooth’.

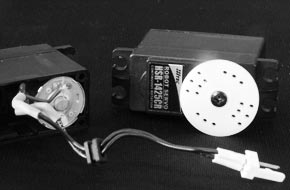

ITCHY – Power Dynamo

Itchy generates power through a small servomotor. The servo-controller was removed in order to make the power generation more efficient regardless of the direction that the motor gears are turned. With a large enough handle on the motors shaft, it takes little effort to generate a decent amount of power, through the motor.The motor is positioned behind the neck of the user in order to get a sufficient range of motion to generate power. As a result, a Sintra ledge jutting out from the back was created and attached with screws and bolts through the outer layer of the dress to an inner Sintra layer, carefully molded to sit on the shoulders.

In order to maximize the power output of the generator, the neck-wrap connected to the dynamo has a varied density throughout. The core materials of the neck-wraps are foam, semi-rigid wire and Sintra plastic. The wire keeps the curve of the wrap to an ideal radius, allowing for optimal motion, which translates into optimal power generation.